Description

Tunnel jet fan

Parsa Fan Tunnel Jet Fan

Tunnel ventilation systems that use tunnel jet fans are the most complete ventilation systems and use the highest technology. These systems can meet all the needs of tunnel ventilation and fully ensure the safety of these vital parts of the road.

Parsa Fan Ventilation Standard Tunnel Jet Fan

Use of Parsa Fan tunnel jet fan in tunnel ventilation systems

-

Type of ventilation (longitudinal, semi-transverse or transverse ventilation)

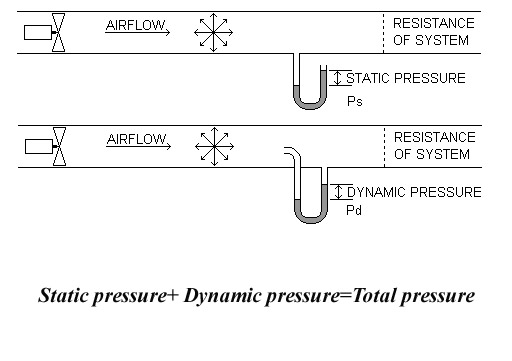

Loss factor that reduces air velocity

Types of Parsa tunnel fan jet ventilation fan

Ordinary jet fan.

The simplest models of tunnel jet fans are ordinary models that can ventilate the air at a constant angle and direction. Most jet fans used in tunnels are of this model.

Reversible tunnel jet fan .

Some jet fan models use airflow reversing capability for high performance. Reversing the airflow system is done using two-way impellers and high-performance motors. In cases where the direction of pollution changes or the air conditioning system has a problem, the tunnel jet fan can change the direction of air flow to prevent the accumulation of pollution. The special sensors used in this tunnel jet fan system can also change the direction of air flow to prevent the progress of smoke by detecting fire and high smoke, and thus will also help in terms of tunnel safety.

Flexible tunnel jet fan or banana.

As mentioned above, ordinary models are fixed and the input and output of the jet fan cannot be adjusted. On the other hand, flexible models can have inputs and outputs that are not directly in the same direction. These fans are used in places that have an arch or curvature. In this way, based on the angle in the tunnel, the inlet and outlet of the jet fan are also adjusted to completely cover the entire space.

Induction jet fan.

Components of Parsafan Tunnel Jet Ventilation Fan

Engine.

Shell.

Impeller.

Advantages of using ParsaFan tunnel jet fan

Tunnel air conditioning.

Help in case of fire.

Use the silencer.

Tunnel jet fan applications

-

Ventilation inside the tunnels and removal of pollution.

-

import fresh air for people to breathe in cars as well as car engines.

-

Prevent the accumulation of smoke and eliminate the risk of explosion and fire.

-

Help prevent the spread of fire during fires in tunnels