Description

ParsaFan welding smoke purifiers

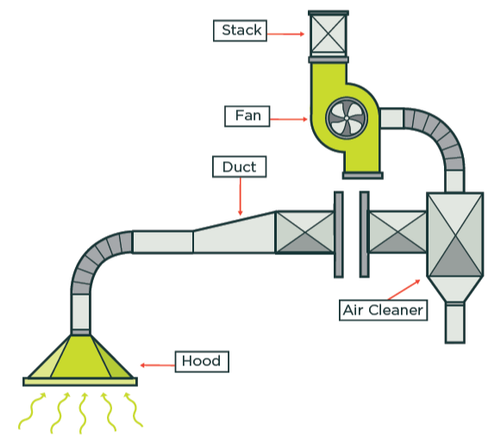

At ParsaFan Ventilation, we offer a wide range of welding air purification systems and welding smoke extraction filters to provide your business with the safest working environment for your employees in the vicinity of the welding process.

Exposure to hazardous welding fumes and dust increases the risk of lung-related diseases, including occupational asthma, metal smoke fever, pneumonia and even cancer. Steam from hot welding and cutting processes is a mixture of airborne gases and very fine particles that, if inhaled, can be harmful to health.

Welding fumes are more annoying than expected during the welding process. Harmless smoke potentially improves living conditions. However, installing a properly designed welding smoke extraction fan and welding air purification system used in accordance with standard instructions will ensure that the steam escapes and creates a safer working environment.

Air filter system for welding ParsaFan mobile extraction arm

Mobile smoke extraction unit of ParsaFan Ventilation Company

Due to its flexibility, our company’s portable welding smoke extraction unit provides filtration for a variety of welding applications including: manual welding, MIG / MAG / TIG welding and gas welding.

Welding smoke purifiers have several features, including:

Mobile unit with castor

Simple filter management

Modular design

Control elements in the front panel

Rugged steel body with powder coating

Volume flow control: stepless adjustment of suction capacity

Loaded Particle Filter Marker: Optical Visualization

Risks associated with the welding process

These hazards can raise concerns about exposure even when welding on conventional carbon steel. Recent research has identified problems with manganese, chromium, nickel, and other potentially toxic metals in boiling smoke. OSHA has recently released new regulations focusing on the carcinogen hexavalent chromium (CrVI or Cr6 +). These health hazards, together with the welders’ perceived reluctance to wear a mask under the welding hood, mean that better approaches are needed to remove welding smoke from the welder’s breathing area.

The importance of boiling smoke extraction

Occupational safety and health in production and manufacturing has become increasingly important in recent years. This has become part of the job instead of annoying. Production processes have become more complex and existing pollutants have become smaller and more bizarre.

Welding smoke extraction and filtration is important. Why? Pollutants of any size may affect humans, machinery and products. High absenteeism rates due to illness or even serious illness of employees have negative economic effects on a company, just like inefficient machines due to pollution. The costs of maintenance, rework, and ultimately loss of reputation and declining demand are predominant adverse effects. Boiling smoke obviously has a direct impact on the health and quality of production.

The absorption of pollutants is regulated by law in different countries. These regulations define the risk classification for specific hazardous substances, for example in a variety of destructive health effects (carcinogenic, mutagenic or disturbing to reproduction).

Reasons for using welding smoke purifier:

- Large amounts of hazardous pollutants are extracted

- There is relatively little effort to get

- Good filtration opportunities are given

- Low energy consumption is possible