Description

ParsaFan High Pressure Radial Fans

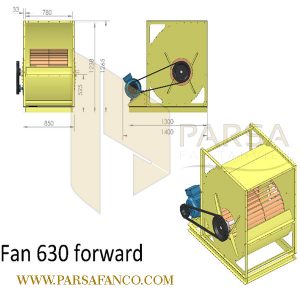

Types of high pressure fans ParsaFan

Design of ParsaFan high pressure radial device

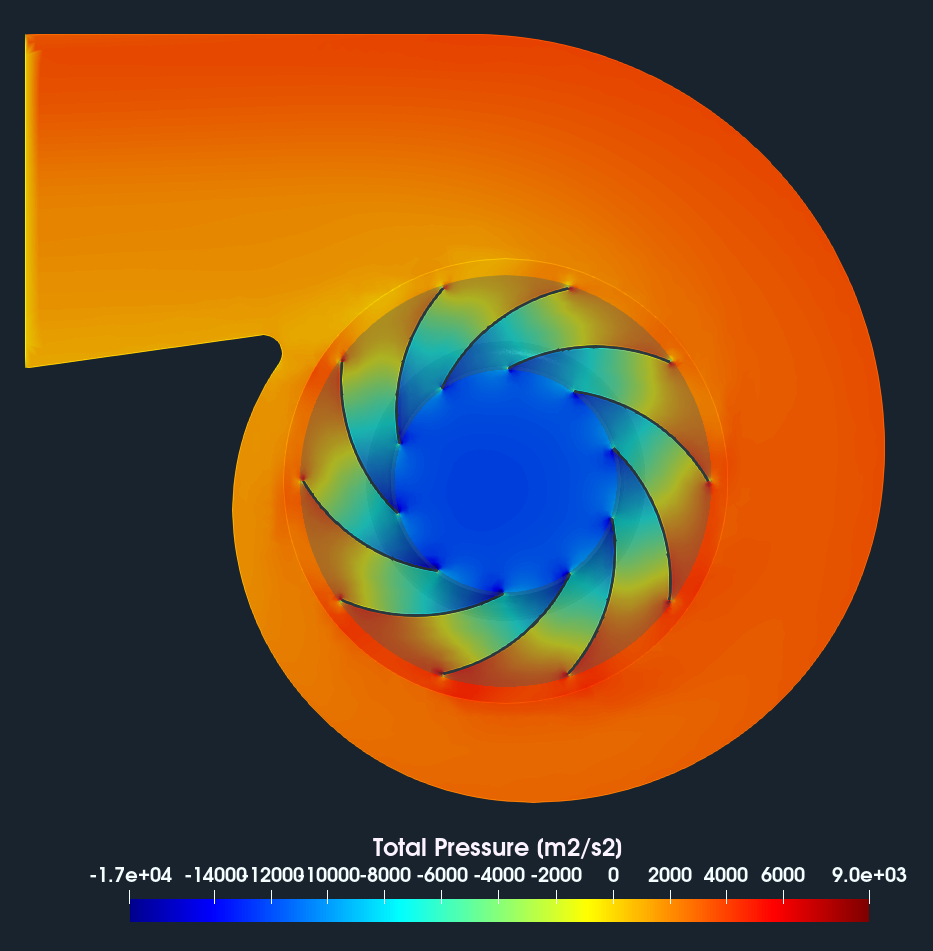

In efficient and durable designs, backward-sloping blades are used to hold particles inside the chamber and on the contact area of the impellers.

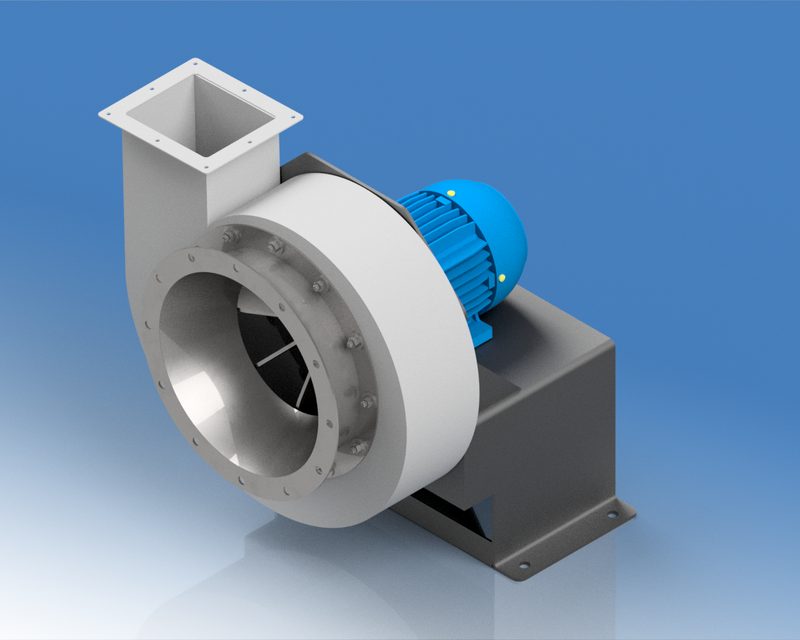

Parsafan high pressure centrifugal fans are very narrow and their impellers are closed except in the eye part and the circumference of the circle. These fans are very efficient and suitable for applications with high static pressures. They are made of stainless steels and strong alloys.

These devices can be opened from the middle in suitable and efficient designs of high pressure furnaces. In fact, it is possible to assemble the housing and thus clean the impellers without interfering with the inlet and outlet parts such as ducts or dampers. These fans are suitable for pressures up to 20,000 Pascals. Due to the high heat generated during the operation of these devices, the shafts can be cooled to increase their service life. These fans make a lot of noise, but a noise canceling device can be used. In order not to damage these devices when exposed to corrosive gases, liquids and solids, strong coating materials can be used that prevent corrosion and physical damage to materials and metals.

Can ParsaFan high pressure centrifugal fans be used as an air conditioner?

These fans are generally rarely known as air conditioners or air conditioners, and this is because the high pressure resulting from the operation of their impeller wheels allows the environment (especially the area around the outlet) Man does undesirable to breathe.

However, if these devices are properly managed and the environment in which they are placed is large, they can be used as air conditioners. Of course, keep in mind that in order not to damage these devices at high pressures and vacuums, durable and strong materials must be used to connect the channels to their inlets or outlets.

Industrial air conditioning systems used in such factories and work environments must be carefully monitored and their pressure and other parameters.

High pressure centrifugal fans can be used in applications where the location of the fan is far from the desired environment or even in places where large spaces are to be ventilated by a single fan. In these cases, the fans have to deal with various factors such as the maze of ducts, dampers and the prevailing pressure in each room. As the channel lengthens and the transverse surface expands, the pressure along the path to the final destination decreases continuously. For such applications, custom centrifugal fans must be used to meet the requirements.

Radial high pressure fans

For pressure testing applications, dust removal and solid aeration are excellent. Duct collectors can be connected to the outlet of a centrifuge fan, helping them to draw air out of the room. In addition, the fan inlet valve can be connected to a duct that expels air through a curved tube.

The result of talking and consulting with experts who have years of produce and experience in this field tells us that if high pressure centrifugal fans are designed in the right balance, they can have the best possible performance.