Radial fan

Radial fan

Radial ventilator (fan)

Radial fans or ventilator are vertical axis fans, that is, they suck air from one side and blow it at a 90 degree angle to themselves.

In radial fans, the pressure drop with respect to air movement is higher than axial fans, so in places where we only need to move air from one point to another and also do not have a pressure drop, axial fans We use. We also use radial fans in environments where we want to move air from a farther place where there is a duct or an obstacle in the airway.

In general, radial fan or fan is divided into two categories, forward fan and backward fan.

There is another category of fans that is divided into single fans (centrifuge) and double fans (blowers).

Radial fans or fans have a spiral shape that sucks air from one side and throws air from their own 90 degree angle.

In single centrifugal fans, this suction is located on one side and the air outlet is at a 90 degree angle. In a double fan, this suction is done on both sides and from both sides at a 90 degree angle.

Forward fan:

Forward fans, as the name implies, are fans with forward curvature, and the direction of rotation must be towards the outlet. In forward fans, the number of single blades is high and the width of the single blade is low.

In forward fans, it does not matter whether the output fan is right turn or levorotatory, it is important that it works with a forward curvature relative to the outlet.

Fan Backward:

Backward fans are fans that move backwards with a curve and must be in the direction of rotation of the backward fans relative to the fan outlet.

In Backward fans, the number of single blades is less and the length of single blades is more.

In the same situation, forward fans have the ability of less speed, but backward fans work with more speed.

The main difference between backward and forward fans is in pressure drop tolerance. Forward fans have less pressure drop tolerance than backward fans. One of the reasons they can withstand less pressure drop is because of the structure they have, they can rotate less.

The pressure is directly related to the impeller circumference and impeller diameter. This means that the larger the impeller diameter, both in the forward fan and the backward fan, the more pressure it creates, and also the more revolutions it makes, the more pressure it creates.

As mentioned before, we can not use more distance in forward fans because they can withstand less pressure drop. That means we can use forward fans to some extent.

Flow and pressure determine the size of the fan, we may use 3000 rpm fans in the forward fans, but in small sizes, which have a higher speed tolerance. This in small sizes can be higher pressure than the flow Create. This means that if we want to consider in smaller fans we can use forward fans, but in this case the air volume or air capacity is reduced, but in backward fans we can use higher speeds.

There is no speed limit on backward fans. ParsaFan Company produces backward fans up to 6000 rpm, relative to pressure and flow.

Because of the longer blades in Backward fans, it can withstand more pressure, which is both dynamic and static pressure. But forward fans can withstand less pressure.

In fans, whether forward or backward, we have two types of blowers (double forward fan or blower – double backward fan or blower). Double fans are used in places that we want to use for drilling. This means that in environments where we want to inject air, we can use a double forward fan, which has a larger volume of air than a single fan. But if we want to use a centrifugal or one-way fan, we must consider a larger size and more round .

If the double fans are placed inside the box, they can do both suction and dehumidification. This means that the double fan can be used as both a sucker and a blower.

In cases where we need more air volume and less pressure drop, we should use the forward fan, and in cases where the pressure drop goes higher, we should use the backward fan.

In general, the efficiency of backward fans is higher than the forward fan. It uses less kilowatts in backward fans at equal flow and pressure.

The important point about Backward fans is that, we in Iran do not have any standard and reference that we want to use. ParsaFan Company references are references of foreign companies such as Nikotra, Kamfri, Zilabag that the fans produced by Parsa Fan Company are made according to the standards of the mentioned companies.

The first advantage of the mentioned companies is that they use backward press fans due to increasing the fan efficiency and lowering the decibel of the fan sound. That is, in the fan inlet funnel, the impellers are funnel-shaped so that we can create the highest cross-sectional area as well as the highest pressure.

When we want to choose a fan, we want to know what flow it gives us in different pressure drops.

Suppose we have an air conditioner, in which various factors are used, such as filters, coils, and so on. In addition to the internal pressure inside the air conditioner, we also have external pressure, which causes the pressure drop to drop through the ducts, knees and valves.

We can calculate the internal pressure drop accurately, but no matter how much we calculate the external pressure drop, it will eventually vary in performance, and we need to know what changes the fan flow makes to the pressure. In addition, in the pressure We have internal filters (types of filters: aluminum filters, G4, F7, F9, H13). These filters are clean on the first day, meaning the pressure drop is obvious, but when they get dirty, clogging occurs, the pressure drop goes up. So when the pressure drop increases, the air volume decreases.

So we need to know how this fan works when the filter gets dirty and there is more pressure drop, that is, how much the flow is reduced.

It should be noted that in forward and backward fans (it does not matter if it is double or blower – single or centrifugal), in forward fans, whether double or single, there is no funnel, but to increase fan efficiency and lower the fan noise, A funnel (or horn) is used in the housing part of the fan.

Other companies make the housing smaller than the impeller opening because they do not have machines, facilities or presses. However, ParsaFan Company, with its advanced machines and presses, puts the housing on the body of the funnel, which reduces the decibel of sound.

The important point is that in the forward fans, because we do not need to tolerate high pressure drop, there is a distance of 5 to 15 miles between the funnel and the impeller. But in backward fans, the impeller must have a funnel, a funnel must go inside the impeller, and the smaller the distance between the funnel and the impeller, the more pressure we can create.

When the backward fan operates at high speed, an air flow is created inside the housing which comes out of the fan opening. Now, if there is a gap between the hopper and the impeller, the air stored inside the housing circulates inside the housing again, which is why In Backward fans, it does not matter if it is double or single, it must be a funnel inside the impeller.

Showing all 7 results

-

Direct drive radial fan or Transportation of materials

Read more -

Double backward fan

Read more -

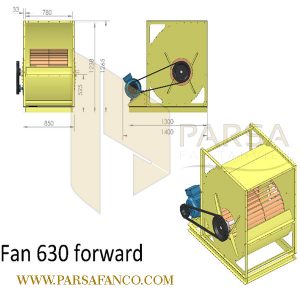

Double forward fan

Read more -

Fan plug

Read more -

High pressure radial fan

Read more -

Single backward radial fan

Read more -

Single forward fan

Read more